GAS PRESSURE REGULATION

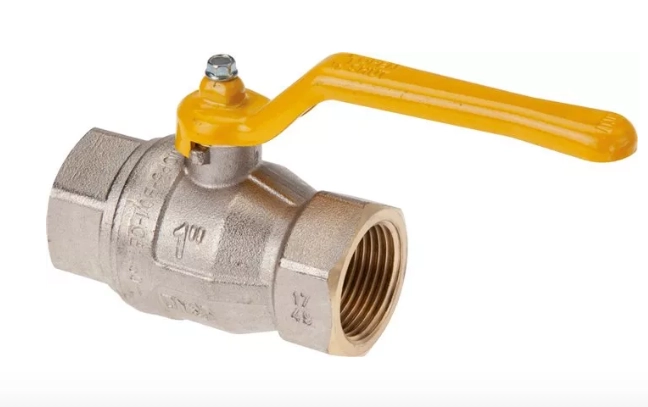

The function of Gas Pressure Regulators is to reduce the pressure of the gas that is available to the gas pressure required by the heater and by the heating controller.

The gas supplied to a gas pressure regulator comes in different, sometimes fluctuating pressures. Just as importantly the need for heating changes over time so the heat output should be adjustable.

Things to keep in mind when selecting the proper gas pressure regulator are:

- Which Gas Type is available?

- At Which Gas Pressure?

- Which Heater Type does the client want to use?

- How do we want to control the heating capacity?

- Manually

- Automatically

- On/Off

- Continuous Regulating

- High-Low

- What Capacity of Gas Pressure Regulators is needed?

Gas Type

Gasolec supplies gas heaters for Propane/LPG or Natural Gas High or Natural Gas Low. Technically all our gas pressure regulators can handle all above gas types, however the gas type used gives information on the gas pressure that is entering the regulation system. Assuming local regulations allow it, we see with:

| Propane | 1.5Bar inlet pressure is normally available |

|---|---|

| LPG/Butane | 0.5 – 0.7Bar inlet gas pressure is normally available |

| Natural Gas | The inlet gas pressure can vary a lot: 25mBar / 50mBar / 300mBar / 960mBar / 2 Bar / please check locally |

Inlet Gas Pressure

The capacity of a gas pressure regulator is determined by the Inlet Gas Pressure, the desired Outlet Gas pressure AND the type of Gas that is flowing through the unit. As a rule of thumb one can say that when we change the gas pressure 4x, the capacity in kg going through the same unit changes 2x. For example: when the gas pressure from an S8 for 350-1400mBar Propane is lowered from 1400mBar to 350mBar (4x) then the heat output drops from 100% to 50% (2x)

Heat Output Adjustment

By increasing or decreasing the output gas pressure we can raise or lower the heat output of many Gasolec heaters. Based on the gas pressure regulation system the Gasolec heaters can be divided into two groups:

Heaters with a central Gas Pressure Regulator operating at various gas pressures

Heaters with a Fixed Operating Gas pressure & individual ignition system

Gas Pressure Regulation Systems

Manual Regulation

The output of most Gasolec S-type and M-type Heaters can be regulated by a manual gas pressure regulator.

- Simple

- Cheap

- Works without electricity

One needs to check the setting oftenBecause of that the heat output is often too high or too low

Automatic Regulation

With automatic regulation we mean that a central climate controller measures the temperature and decides if extra heating is needed by sending either an ON/OFF or a 0-10Vdc control signal to the heating system or not. We recommend using a central controller that takes care of the complete climate, meaning heating + ventilation + air inlet control + cooling system.

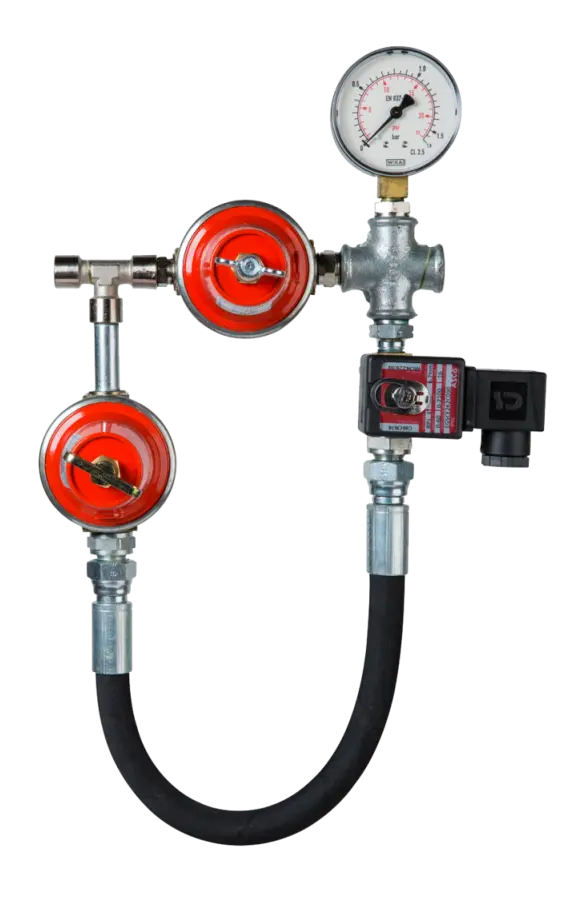

Automatic Regulation - High-Low

Here the High-Low Unit receives power when heat is needed and then it goes to a High gas pressure = high heat output. When this power supply is cut, the unit goes back to a Low gas pressure = low heat output. In most cases one can adjust the minimum and maximum by hand in case there is an interruption of the power supply.

The larger the difference between the Maximum and the Minimum gas pressure to a heater, the more gas saving is possible during periods when there is no need for the maximum output.

- Still relatively simple

- Gas savings through better use

- Can be connected to climate controller

- Manual Control also possible

Abrupt gas pressure changes can lead to uncalled gas flow interceptions by the sometimes locally required gas-hose-leakage-detectors

Automatic Regulation - Continuous (Step Less)

Here a 0-10Vdc control signal from the climate controller plus a 24V power supply go to the GPC 300 series gas pressure control unit. The GPC unit is a continuous gas pressure control unit that changes the gas pressure and thereby the heating output gradually. At the same time, these gradual pressure changes don’t lead to interruptions by gas-hose-leakage detectors where gas leakage would be noticed.

- Can be connected to climate controller

- Unit equipped with manual control option as emergency solution for power interruptions

- Changes in room temperature go very slowly

- No problems with uncalled for interruptions in the gas supply by gas-hose-leakage-detectors

More expensive than a High-Low unitHigher gas consumption

Automatic Regulation with fixed gas pressure – ON/OFF

All G12 heaters operate in principle on 28mBar. Usually the gas pressure to these heaters is set at 30mBar which allows a 2mBar gas pressure drop over the gas hose.

The G12 Asco is automatically controlled with an ON/OFF signal from the climate controller, similar to working with a High/Low Regulator only the minimum and maximum are not adjustable. The G12E actually operates at Maximum or it is Off.

The G12 Maxi works with a fixed gas pressure and a Capillary Thermostat that is manually set and that controls the heat output automatically. This model is popular in areas with electricity supply problems and in poultry houses with big differences in temperature in the same building.

Some customers prefer a central gas pressure regulator with a 30mBar output which they source locally. At Gasolec we recommend working with a 400+mBar gas pressure in the gas lines and to use a gas pressure regulator set at 30mBar with each heater. This individual gas pressure regulator PR30 is intended to absorb pressure fluctuations in the gas line when groups of heaters are either switched ON or OFF AND by working with 400+mBar in the main line, one can work with smaller diameter gas lines (= cheaper and less heavy!).

Determining the Size of the Gas Pressure Regulator

To produce 1kW/h one needs 72gram of propane/LPG. This leads to:

S8, capacity 3.5kW -> 252gr/h at full capacity

M8, Capacity 5kW -> 360 gr/h at full capacity

For example – using the Gasolec Heaters and the Gasolec Gas Pressure Regulating units:

- A Broiler House equipped with 15x S8 means a maximum Gas Consumption of 3.78 Kg/h => it needs a gas pressure regulator with at least a 4kg/h capacity.

- A Broiler House equipped with 30x M8 operating in one group means a maximum Gas Consumption of 10.8 Kg/h => it needs a gas pressure regulator with at least a 12kg/h capacity.

With Natural Gas the situation is quite different as usually the inlet gas pressure is much lower => the capacity of the gas pressure regulators is much less. Please check your options with your supplier or with Gasolec.

NOTES:

- When in doubt what system to pick, please contact your local dealer or Gasolec first. Each Gas Pressure Regulating System has its own specific advantages and depending on the wishes of the customer as well as local regulations Gasolec can help you choose your optimum solution.

- Each heater is designed especially for a certain gas type & gas pressure, changing the gas type and/or gas pressure without changing the heater specifics can lead to serious problems!

Downloads:

- Gasolec_HLM_25kg_High_Low_Regulator_20-1400mBar_20-300Mbar_-_31-07-2020.pdf 162.03 KB 29-04-2021

- Gasolec_HLM_12kg_High_Low_Regulator_20-1400mBar_20-300Mbar_-_31-07-2020.pdf 175.93 KB 29-04-2021

- Wiring_Manual_GPC_300_-_22-07-2020.pdf 218.08 KB 29-04-2021

- Gasolec_HLS_50-190_4kg_230Vac_or_115Vac_-_24-7-2020 (1).pdf 61.31 KB 29-04-2021

- Gasolec_HLS_50-190_4kg_230Vac_or_115Vac_-_24-7-2020.pdf 61.31 KB 29-04-2021